Hossein M. Shodja

Molecular dynamics simulation method was employed to model mode I crack propagation in plates containing nanoscale clusters of impurities located in the vicinity of the crack tip. The plates and the clusters were considered to have an fcc structure. The interactions between the dissimilar atoms in the plates and clusters were modeled via the many-body Sutton–Chen inter-atomic potentials [Sutton, A.P., Chen, J., 1990. Long-range Finnis–Sinclair potentials. Philos. Mag. Lett. 61, 139–164], and their extended versions developed for fcc alloys by [Rafii-Tabar, H., Sutton, A.P., 1991. Long-range Finnis–Sinclair potentials for fcc metallic alloys. Philos. Mag. Lett. 63, 217–224]. In this paper, two different geometries for the clusters, in the form of a long strip and a cylinder, were considered, and their effects on the critical load and crack propagation were examined. Before reaching the critical load, the temperature of the system was held constant at 0 K by applying both a simple temperature scaling method and the Nose–Hoover thermostat [Rafii-Tabar, H., 2000. Modelling the nano-scale phenomena in condensed matter physics via computer-based numerical simulations. Phys. Rep. 325, 239–310]. The temperature was allowed to evolve, however, during all the subsequent stages of crack propagation. Velocity Verlet algorithm [Allen, M.P., Tildesley, D.J., 1987. Computer Simulation of Liquids, Clarendon Press] was employed to integrate the equations of motion.

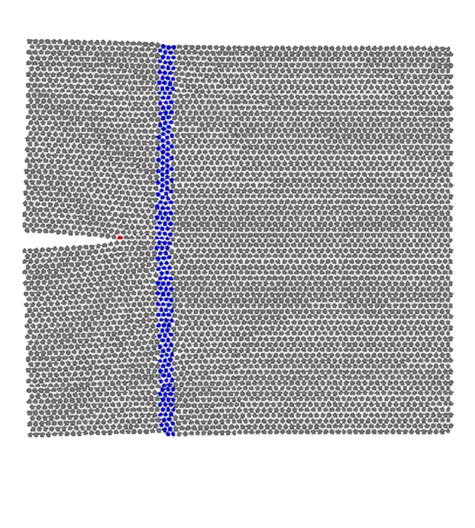

Formation of a dislocation when a Cu impurity ispresent in an Ag plate under critical load.

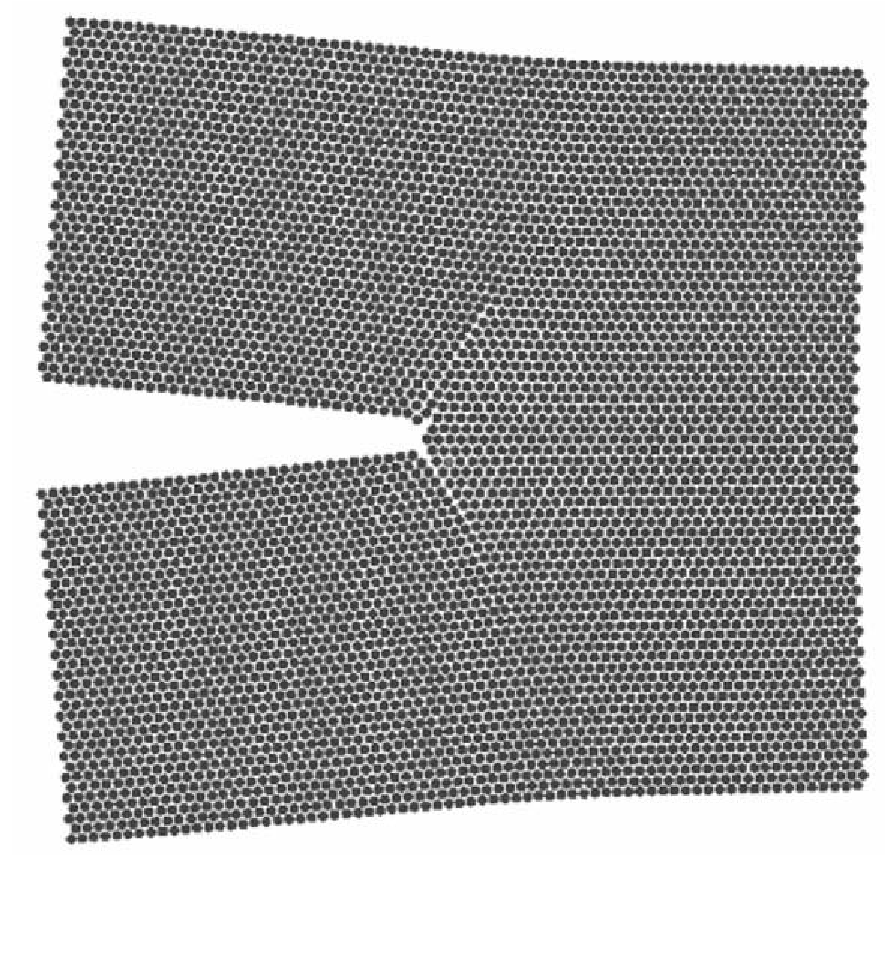

MD simulation snapshot of crack propagation in pure Ag in which the bifurcation phenomenon is clearly observable.

Molecular dynamics simulation, crack propagation, fcc materials